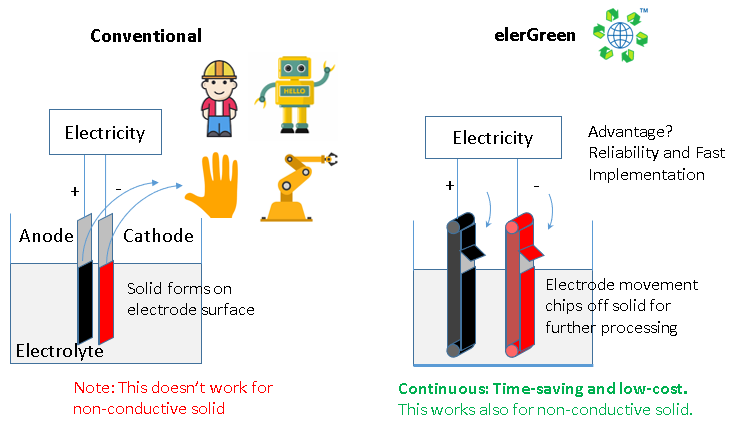

elerGreen process involves a core reactor design that is innovative in nature. Conventionally, electrochemical reaction involved removing solid deposits from the electrode, either manually or by robotic arms. Such conventional method however is not only higher cost, but also does not work for non-conductive solids that blogs the electrode quickly.

elerGreen reactors involved continuous solid removal by cyclic motion thus removing the conventional limitations against electrochemical production of polymers.

The reactor design also received interests from electroplating industry for its lower cost and reliability.